Performance

Inspection Standards: GB/T 11260-2008 Eddy Current Inspection Method for Round Steel and GB/T 7735-2004 Eddy Current Inspection Method for Steel Tubes

Longitudinal artificial injury: 0.10 (depth)x 0.10 (width)x 20 mm (length)

Conditions of pipe and rod end: deburring of guide angle at both ends, cross section deformation equal to less than diameter tolerance

Flatness tolerance: maximum tangent direction 1.5 m m/m, and not exceeding the total length of the whole workpiece

Diameter Tolerance and Ellipticity: Reference to DIN Standard

Technical Performance Index of Rotary Flaw Detection System

(1) The eddy current flaw detector can record, alarm and mark the defect detection results of finished steel pipe accurately, reliably and stably.

(2) Inspection speed: <60 m/min

(3) Detection of end-to-end blind area: 50mm signal-to-noise ratio: > 10dB

Missing report rate: 0%

The false alarm rate of sample rod is less than 2%.

Stability: 2 hours later < 1dB

Accuracy of spray mark: + 30mm

Circumferential sensitivity difference: <1dB

(4) 100% coverage test, the instrument set up upper and lower boundaries, exceeding or below the automatic alarm record;

(5) Operation mode of flaw detector: fully automatic and complete electronic control system, testing instrument and auxiliary control.

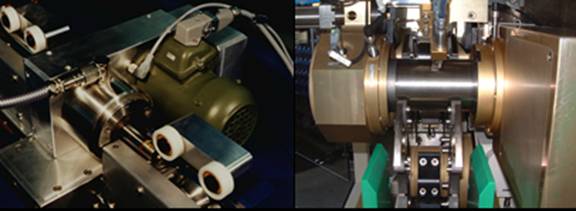

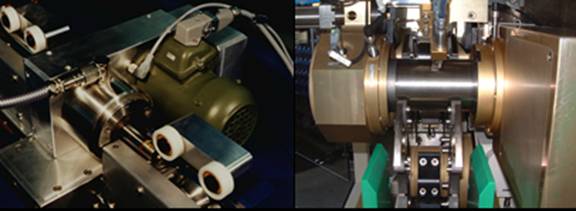

The high-speed rotating detection system has the following important characteristics

(1) Precision positioning and driving mechanism technology in pipe bar inspection;

(2) The probe is rotated and the pipe rod moves in a straight line, which has the advantages of high speed, low noise, reliability and high sensitivity.

(3) Multi-channel noise suppression technology.

(4) The gap between the steel rod and the probe can be adjusted continuously and accurately without changing the probe.

(5) The signal is processed by high-speed DSP signal processing mode, each channel signal is processed independently, and the signal-to-noise ratio transmitted is high.

(6) Wireless transmission technology, without sparks;

(7) It has a long service life and the smallest vertical blind area.

(8) No change of probe rotation detection technology;

(9) The equipment can run steadily all the year round.