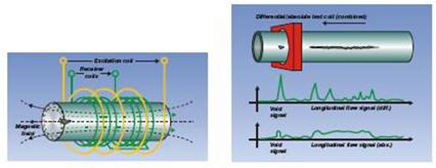

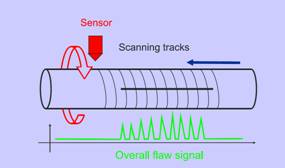

BKNET-101 eddy current flaw detector can quickly detect surface cracks, dark cracks, air holes, inclusions and opening cracks of various metal tubes, rods and wires with high sensitivity.。

BKNET-101 eddy current flaw detector has a testing frequency range of 100Hz-1MHz. It can meet the testing requirements of various metal pipe diameters, a variety of unique alarm modes, fast automatic electronic digital balance and full digital design. Therefore, a standard testing procedure can be established in the instrument, which is convenient for users to call when changing materials of different specifications. At the same time, 24-hour real-time storage of detection data, real-time detection "well-founded" to ensure that the review of "0" defects.