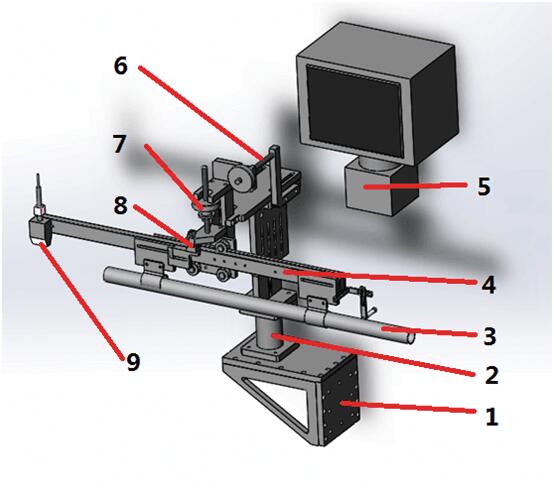

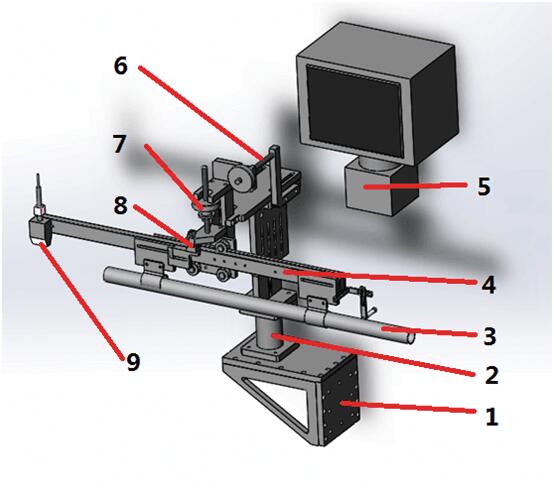

1:Fixed rack 2:Support frame 3:Discharge pipe 4:Left and right adjusting lever 5:Eddy current flaw detector

6:Front and rear trimming 7:Upper and lower trimming 8:Collision avoidance device 9:Eddy current probe

|

Test beat |

Large rollers, 60pieces/min; Medium rollers, 120pieces/min; Small rollers, 180 grains/min |

|

Detection speed |

1~3pieces/s |

|

Frequency range |

10Hz~10MHz |

| Gain |

0~99dB,side size 0.1dB |

|

Advanced filtering |

Yes |

|

High pass |

0.1Hz~650Hz |

|

Low pass |

1Hz~10000Hz |

|

Phase rotation |

0-360° side size 1° |

|

Flaw detection accuracy |

Crack length * width * depth (3 * 0.01 * 0.05) mm |

| Synchronized alarm output controlled by internal and external clock |

| High Precision End and End Signal Excision Function |

| High Precision Real-time and Delayed Alarm Output |

| Fast Digital/Analog Electronic Balance |

| Delayed Hidden Removal Function with Memory Trajectory |

| Real-time impedance plane display |

| The instrument can match any probe |

| Remote Automatic Help System |

| Man-machine interface in Chinese and English |

|

Non-equal Amplitude Phase/Amplitude Alarm Domain |

| Computer Full Digital Parameter Adjustment |

|

Automatic Statistics of Total, Bad Products, Qualified Number |